About Blank Draw Press Machine

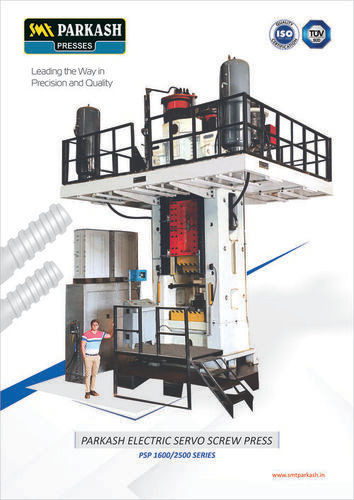

MAIN FRAME:

PRAKASH Presses with robust HORIZONTAL RING FRAME construction gives highest rigidity minimizing deflection of the frame to almost zero thereby giving incredible tools life & part quality. The tools are mounted under heavy tie rod construction for zero tolerances. Oil dip gears provided to enhance press life & low sound level. No open parts for the highest safety of operator.

COIL FEEDER:

Servo controlled coil feeder feeds the coil directly onto the die from the decoiler. The feeder moves the coil in a zigzag pattern inside the frame of the press for providing you maximum efficiency from the coil. You can have up to 86% recovery from the coil depending upon the component.

LINK MOTION DRIVE:

Three times slow draw speeds compared to faster return speed ensures good draw part quality with minimum rejection & still FASTER PRODUCTION.

AUTO GAUGE VARIATION CONTROL:

Auto gauge variation control system draws blanks even with thickness variation minimizing rejections. Motorised blank holders reduce die setting time unbelievably just at the touch of a single button without any manual settings by operator.

PRODUCTION : 2100 pcs/hr (variable)

ADVANTAGES:

- Improved quality for the component*

- 800% saving in labour cost*

- 600% saving in power consumption*

- 600% saving in area (space)*

- Zero blanking cost

- Reduced scrap

*as compared to normal double action press

FEATURES:

- Recirculating lubrication system

- Maintenance & lubrication free bushes/bearings

- Automatic draw compound spray nozzles

- Conveyor system

OPTIONAL FEATURES:

- Hydraulic tool clamping

Superior Performance and CapacityDesigned to handle rigorous blank drawing and forming processes, this hydraulic press operates with a maximum force of 100 tons. Thanks to its 350-liter oil tank and powerful 15 HP motor, it achieves a production rate of up to 60 sheets per hour, making it suitable for high-demand manufacturing environments.

Designed for Safety and DurabilityFeaturing reliable safety guards, a robust H-frame structure, and durable mild steel construction, the machine not only ensures operator safety but also withstands continuous industrial use. Its semi-automatic operation and slide adjustment up to 80 mm increase convenience and adaptability to different production needs.

Versatile and Efficient OperationWith its large bed (900 x 800 mm) and adjustable stroke (300 mm), this press accommodates various die sets and workpieces. Its three-phase 380-415 V capacity ensures powerful, efficient performance for exporters, manufacturers, and suppliers across multiple industries in India.

FAQs of Blank Draw Press Machine:

Q: How does the Blank Draw Press Machine operate?

A: The Blank Draw Press Machine functions via a semi-automatic hydraulic system, allowing for consistent blank drawing and forming with minimal manual intervention. Operators use a control panel to manage the machines cycles and settings, ensuring efficient and safe production.

Q: What materials and applications is this press suitable for?

A: This machine is primarily built using mild steel for high durability and is specifically designed for blank drawing and forming operations. It is ideal for sheet metal processing in automotive, appliance, and general metalworking industries.

Q: When should I perform maintenance on the press machine?

A: Routine maintenance, such as checking hydraulic oil levels, inspecting mechanical parts, and ensuring safety guards are intact, should be performed every 250-500 hours of operation, or as recommended in the manufacturers manual, to maintain optimal performance.

Q: Where can I install this machine in my facility?

A: Given its dimensions (3100 mm x 2100 mm x 2800 mm), the machine should be placed on a stable, level surface in a well-ventilated, industrial production area with access to a 380415 V three-phase power supply.

Q: What is the process for changing die sets on this machine?

A: To change die sets, the operator must power down the press, open the safety guards, and use the slide adjustment (up to 80 mm) for precise die positioning. Always follow the safety guidelines detailed in the machines user manual.

Q: What benefits does the Blank Draw Press Machine offer over other press types?

A: This hydraulic H-frame press provides superior force distribution, increased safety through integrated guards, high customization via slide adjustments, and efficient semi-automatic operation. Its production speed and capacity make it a cost-effective investment for high-volume sheet manufacturing.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry