Deep Drawing Dies

Deep Drawing Dies Specification

- Working Process

- Deep Drawing

- Life Span

- Approximately 500,000 cycles

- Die Head

- Interchangeable Die Head System

- Shaping Mode

- Cold Forming

- Material

- High Carbon Steel / Tool Steel

- Application

- Automotive, Electronics, Kitchenware, Industrial Components

- Hardness

- 58-62 HRC

- Tolerance

- 0.01 mm Millimeter (mm)

- Operation Speed

- Up to 60 strokes/min

- Die Base Material

- Alloy Steel

- Max Drawing Depth

- Up to 250 mm

- Coating

- Nitriding / PVD / Black Oxide

- Cavity

- Single or Multi-cavity options

- Die Type

- Progressive Die, Transfer Die, Compound Die

- Max Blank Diameter

- Up to 500 mm

- Customization

- Available as per Specification

- Surface Finish

- Polished, Hardened Surface

- Heat Treatment

- Vacuum Hardened

Deep Drawing Dies Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 2-3 Months

- Main Domestic Market

- All India

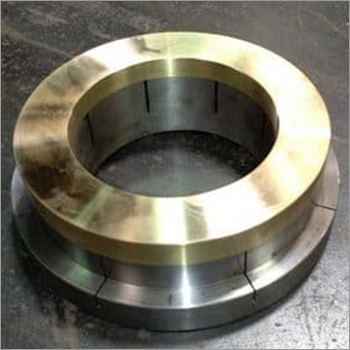

About Deep Drawing Dies

Deep Drawing Dies are widely utilized for sheet forming process with help of blanking machines. They are fabricated using tough metal alloy with galvanized surface finish so as to prevent chances of corrosion. These dies are highly appreciated for producing precise shapes with excellent repeatability. They are known to have sturdy structural configuration with great impact strength. Deep Drawing Dies offered by us are available in customized configurations at highly competitive rates for our respected clients.

Features:

- High deformation resistance

- Hassle-free to install

- Completely reliable in nature

Approx Price: Rs 1 Lakh /Piece

| Usage | Industrial |

| Die Type | Deep Draw |

| Material | Steel |

Owing to our affluent industry acquaintance, we present Deep Draw Die And Mould.

The only source of knowledge is experience. With our experience in the deep draw technology, we have developed certain dies and moulds to have unbelievable life and superior component finish.

High Precision with Durable Construction

Our Deep Drawing Dies are meticulously crafted using alloy steel and finished with advanced surface coatings such as nitriding, PVD, or black oxide. Each die undergoes vacuum hardening to achieve a hardness of 58-62 HRC, ensuring robust performance and minimal wear. Their polished and hardened surfaces reduce friction and enhance part quality, supporting a wide range of applications in demanding industrial sectors.

Versatile Options for Every Requirement

Choose from progressive, transfer, or compound dies, all available in single or multi-cavity formats. Our dies accommodate varying blank sizes and drawing depths, making them ideal for manufacturing intricate automotive, electronics, kitchenware, and industrial components. Operation speeds of up to 60 strokes per minute increase productivity, while the interchangeable die head system allows for quick adaptation to new designs.

Reliable Performance and Custom Solutions

Engineered for consistent operation and long service life (up to 500,000 cycles), our deep drawing dies maintain tight tolerances of 0.01 mm. Customized solutions, including material selection (high carbon steel or tool steel), die shapes, and coating options, are available to precisely match your production needs. Our expert support ensures smooth integration and maximum efficiency at your facility.

FAQs of Deep Drawing Dies:

Q: What types of deep drawing dies are available for different manufacturing needs?

A: We offer progressive, transfer, and compound dies, all crafted to meet distinct production processes. These options are suitable for a range of applications, including automotive, electronics, kitchenware, and more, providing flexibility based on your operational requirements.Q: How does surface finish and coating impact the performance of deep drawing dies?

A: A polished and hardened surface, combined with coatings such as nitriding, PVD, or black oxide, enhances durability, minimizes friction, and prevents wear. This ensures high-quality part surfaces and prolongs die life, even in high-volume manufacturing environments.Q: When should I choose a single-cavity over a multi-cavity deep drawing die?

A: Single-cavity dies are ideal for small batch or large, intricate components that require precise individual attention. Multi-cavity dies, meanwhile, boost efficiency by producing multiple parts per cycle, making them suitable for high-volume production scenarios.Q: What is the maximum drawing depth and blank diameter supported by your deep drawing dies?

A: Our deep drawing dies support a maximum drawing depth of up to 250 mm and can accommodate blank diameters up to 500 mm, allowing the production of large or deep-formed parts with accuracy and consistency.Q: Where can deep drawing dies from your company be used?

A: These dies are widely used in the automotive sector, electronics manufacturing, kitchenware production, and various industrial applications due to their precision, strength, and adaptability.Q: How does the interchangeable die head system benefit my manufacturing process?

A: The interchangeable die head system facilitates rapid die changes, enabling quick adaptation to new designs or part specifications. This reduces downtime and increases overall production efficiency.Q: What are the key advantages of your deep drawing dies for exporters and manufacturers in India?

A: Exporters and manufacturers benefit from consistent quality, high operational speed (up to 60 strokes/min), robust durability (up to 500,000 cycles), and tight tolerances (0.01 mm). Customization options and reliable after-sales support further ensure that our dies meet the precise demands of diverse global markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Deep Draw Dies Category

Dies

Price 2000000-60000000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, High Speed Steel (HSS)

Hardness : 6264 HRC

Working Process : Other, Threading, Forming

Life Span : Long Service Life

|

SHARMA PRESSES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry