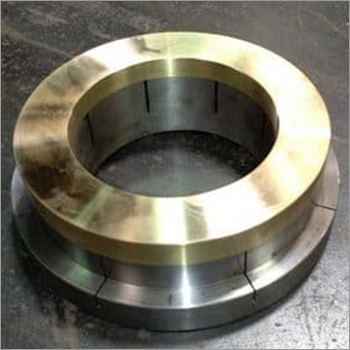

Dies

Price 2000000-60000000 INR/ Piece

Dies Specification

- Working Process

- Threading, Forming

- Die Head

- Round Threading Die Head

- Life Span

- Long Service Life

- Shaping Mode

- Forging, Machining

- Material

- High Speed Steel (HSS)

- Application

- Industrial Threading, Pipe Fitting

- Hardness

- 62-64 HRC

- Tolerance

- 0.01 mm

- Thread Types Supported

- BSPT, BSP, NPT, Metric

- Size (Range)

- Available in multiple sizes

- Customization

- Available upon request

- Packaging Type

- Box Packaging

- Corrosion Resistance

- Yes

- Surface Finish

- Precision Ground

- Heat Treatment

- Fully Hardened and Tempered

- Usage

- Manual and Machine Tool Compatible

- Color

- Silver/Grey

- Coating

- Black Oxide, TiN Coated

Dies Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 2-3 Months

- Main Domestic Market

- All India

About Dies

The only source of knowledge is experience. With our experience in deep draw technology, we have developed certain dies and moulds to have unbelievable life and superior component finish.

Sharma Machine Tools dies division is a fully staffed, equipped with modern tool room and state of the art CNC machines with all the necessary facilities. The company builds everything from complex Draw Dies to Blanking Dies, Blank & Draw Dies, Progressive Dies and Prototype/Special purpose developments.

With skilled workforce, dies has the human and technical resources to take your design concepts upstream to supply a single component or a full sub-assembly. The companys never ending quest for perfection along with significant investment in people, technology and innovation allows us to offer superior services in:

- Long lasting Draw Dies

- Draw Dies for ultimate component finish

- Blank and Draw Dies

- Blanking Dies

- Pillar Dies

- Progressive Dies

- Prototype/Special purpose developments

The company embraces the philosophy of partnership with its customers. The company strives to develop a strong channel of communication with each customer which will ultimately lead to mutual success for both companies. We are eager to answer all your questions regarding deep draw dies or any other query.

Exceptional Precision and Durability

Each die is crafted from high speed steel and undergoes a rigorous forging and machining process, followed by full hardening and tempering. The result is a product with robust hardness (62-64 HRC), excellent wear resistance, and a precision-ground finish that guarantees accurate threading. Additional defensive coatings provide superior corrosion resistance, extending product longevity even under rigorous industrial use.

Versatile Applications and Compatibility

Supporting a broad spectrum of thread typesincluding BSPT, BSP, NPT, and Metricthese dies efficiently cater to the needs of pipe fitting and threading operations across various industries. Designed for compatibility with both manual and machine tool setups, they provide flexibility for diverse manufacturing workflows and project requirements.

FAQs of Dies:

Q: How do these dies ensure precise threading results?

A: Each die features a precision ground surface finish and is manufactured using advanced forging and machining processes. The strict tolerance of 0.01 mm guarantees accurate thread formation, making them ideal for demanding industrial applications.Q: What thread types can be supported by these dies?

A: Our dies are compatible with multiple standard thread types such as BSPT, BSP, NPT, and Metric, allowing them to be used in a wide range of pipe fitting and industrial threading jobs.Q: When should I use these dies for my industrial projects?

A: These dies are best employed when you need robust, accurate threading solutions for pipe fitting or industrial manufacturing, particularly when working with both manual and machine tools and requiring long-lasting performance.Q: Where are these dies suitable for use?

A: The dies can be used in various industrial settings, from mechanical workshops and fabrication facilities to large-scale manufacturing plants requiring efficient and reliable thread cutting and forming processes.Q: What is the typical working process for these dies?

A: The dies are utilized in threading, forming, and shaping operations, featuring a round threading die head for optimum engagement with pipes and fittings during forging or machining action.Q: How does the coating benefit the dies?

A: Coatings such as Black Oxide and TiN enhance the dies resistance to corrosion and wear, increasing their operational life and reliability, especially in challenging environments.Q: Can I request custom sizes or specifications for these dies?

A: Yes, customization options are available upon request to meet specific threading requirements, ensuring optimal compatibility and performance for your specialized industrial projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Deep Draw Dies Category

Deep Drawing Dies

Minimum Order Quantity : 1 Piece

Life Span : Approximately 500,000 cycles

Tolerance : 0.01 mm Millimeter (mm)

Application : Automotive, Electronics, Kitchenware, Industrial Components

Hardness : 5862 HRC

Working Process : Other, Deep Drawing

|

SHARMA PRESSES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry