Ring Frame Double Action Press Machine

Price 5000000 INR/ Piece

Ring Frame Double Action Press Machine Specification

- Material

- Mild Steel

- Power

- 7.5 HP

- Voltage

- 415 V

- Dimension (L*W*H)

- 1600 mm x 1100 mm x 1800 mm

- Application

- Compressing and pressing waste cotton/cotton rags in ring frame

- Accessories

- Control Panel, Hydraulic Oil Tank, Pressure Gauge

Ring Frame Double Action Press Machine Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Week

- Delivery Time

- 1 Week

About Ring Frame Double Action Press Machine

Features:

Low die setting time High production rate Equipped with oil dip gears

- Improves metal flow times by keeping material in the work portion by nearly 300% longer period.

- Slower velocity in the tool improves part finish.

- Faster production speeds without increased forming speed thanks to faster slide return rate.

- Lower impact, shock, noise and vibration improves die, press and other equipment life.

Technical Specification

PRAKASH Press Number | 4 1/2 | 5B | 51/2 | 6B | 7B |

Capacity Total. (Tons) | 100 | 150 | 200 | 300 | 400 |

Capacity Plunger (Punch) (1/4” above bottom) Tons. | 65 | 100 | 125 | 200 | 275 |

Capacity blank holder (1/8” above bottom) Tons. | 35 | 50 | 75 | 100 | 125 |

Inch | Inch | Inch | Inch | Inch |

|

Largest Blank Admitted | 20 | 26 | 28 | 32 | 42 |

Deepest Draw | 7 | 9 | 10.5 | 12 | 15 |

Maximum Stroke of (Pressure Plate) | 8 | 11 | 12 | 14 | 17 |

Max Stroke of (Punch) | 14 | 18 | 21 | 24 | 30 |

Bed to Pressure plate adjustment up-stroke up | 21 | 25 | 28 | 33 | 42 |

Bed to punch Holder adjustment up-stroke up | 24 | 30 | 32 | 40 | 60 |

Bed between frames | 26 | 30 | 32 | 36 | 48 |

Bed font to back | 36 | 42 | 44 | 51 | 60 |

Hole dia. Through bed | 12 | 15 | 15 | 18 | 24 |

Largest dia. Punch admitted | 18 | 22 | 24 | 27 | 32 |

Adjustment to Pressure-Plate | 6 | 7 | 8 | 9 | 12 |

Adjustment to Punch-Holder | 6 | 7 | 8 | 9 | 12 |

Strokes per minute (variable) | 10 | 9 | 8 | 7 | 6 |

Motor H.P. Required (960 rpm) | 15 | 25 | 30 | 40 | 50 |

Overall Height | 120″ | 140″ | 150″ | 170″ | 190″ |

Overall Width | 85″ | 95″ | 105″ | 125″ | 150″ |

Overall Depth | 55″ | 65″ | 70″ | 80″ | 95″ |

Weight Approximate Kg. | 8000 | 13500 | 16000 | 21500 | 32000 |

Efficient Cotton Compression

This machine excels at compressing and pressing waste cotton and cotton rags, commonly generated during ring frame processes. Its double-action hydraulic system effectively reduces bulk, making handling and storage easier while improving overall process efficiency. The sturdy frame and high-pressure system ensure dependable and consistent performance in demanding textile environments.

Advanced Automated Controls

Equipped with an automatic PLC system, operators can control detailed functions with minimal manual intervention. The semi-automatic operation streamlines cycle times to 55 seconds, increasing productivity while maintaining precision. Real-time feedback and monitoring make the handling of cotton waste both safe and user-friendly.

Robust Design and Safety

Constructed from mild steel with heavy duty welded framing, this press machine is built to withstand prolonged industrial use. Safety remains paramount, with features such as overload protection and an emergency stop button, ensuring secure operation for technicians. The system includes a control panel, hydraulic oil tank, and pressure gauge for complete operational readiness.

FAQ's of Ring Frame Double Action Press Machine:

Q: How does the Ring Frame Double Action Press Machine operate?

A: The machine utilizes hydraulic pressure up to 250 Bar, activated through a semi-automatic operation mode and managed by an automatic PLC control system. It compresses and presses waste cotton or rags in a ring frame, completing each cycle in about 55 seconds with a heavy duty welded frame for enhanced stability.Q: What materials can be processed with this hydraulic press?

A: Primarily designed for compressing and pressing waste cotton and cotton rags generated in ring frame operations, the machine can process similar textile waste materials within its rated specifications.Q: When should the emergency stop button be used on the press machine?

A: The emergency stop button should be immediately pressed in any unsafe situation, mechanical malfunction, or if abnormal operation is detected, to halt the machine and prevent damage or injury.Q: Where is the Ring Frame Double Action Press Machine typically installed?

A: This press machine is commonly installed in textile and spinning mills across India, particularly in areas where ring frame waste management and compression are routine tasks. Its compact dimensions allow for easy integration into existing production lines.Q: What is the process for pressing cotton rags using this machine?

A: Waste cotton or cotton rags are loaded into the machine, the cycle is activated via the control panel, and hydraulic double-action pressing takes place under 250 Bar pressure. Each cycle, managed by PLC controls, is completed in approximately 55 seconds.Q: How does using this hydraulic press benefit textile operations?

A: Adopting this press machine streamlines waste management, reduces storage space for cotton waste, improves handling convenience, enhances safety with built-in overload protection, and increases productivity through automation and rapid cycle times.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automotive Press Machine Category

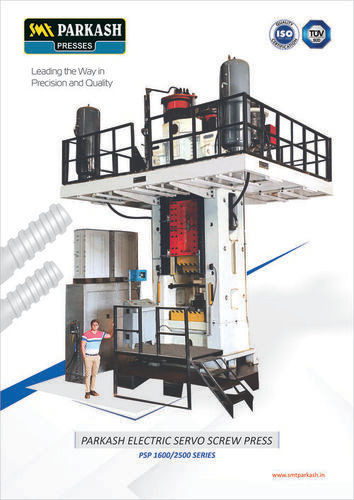

Servo Feeder Press Machine

Price 5000000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Application : Automatic feeding of sheet metal to press machine

Voltage : 220380 V

Dimension (L*W*H) : 1500 mm x 800 mm x 1600 mm

Blank Draw Press Machine

Price 5000000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Application : Blank Drawing and Forming

Voltage : 380415 V (Three Phase)

Dimension (L*W*H) : 3100 mm x 2100 mm x 2800 mm

|

SHARMA PRESSES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry