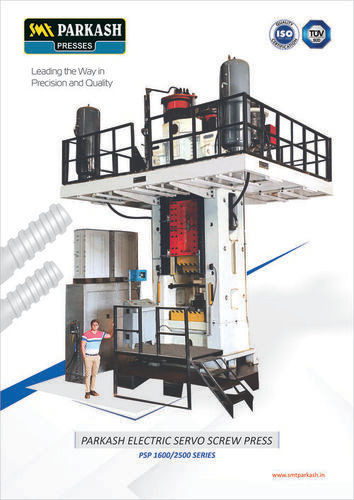

Servo Screw Press

Price 2000000 INR/ Piece

Servo Screw Press Specification

- Material

- MS

- Size

- Different Sizes Available

- Warranty

- Yes

Servo Screw Press Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- Months

- Sample Available

- Yes

- Main Domestic Market

- All India

About Servo Screw Press

The frame of PARKASH Screw Press consist of four steel casted frames, held together by four.jpg)

hydraulicaly pretensioned tie rods, and thus ensuring longevity of the frame, and forming of more accurate parts, and reducing the overall weight and size of the press.

Screw is made of high-alloy forged, quenched and tempered

steel which provides longer screw life. The screw bearing in the

machine frame is a heavy-duty spherical flanged bearing.

Screw Nut

Screw nut is of special wear resistance bronze alloy fixed in the ram.

Thread geometry in the screw drive with optimized tooth profile and four

start threads, has already proved to be durable and tough in the past.

Motors and Driving System of the Press

.jpg) The drive comes from two heavy-duty high torque motors linked via a bull gear to the external diameter of the flywheel. The press force is limited by a slipping clutch provided in the flywheel.

The drive comes from two heavy-duty high torque motors linked via a bull gear to the external diameter of the flywheel. The press force is limited by a slipping clutch provided in the flywheel.

Safety

PARKASH Servo Screw Press is equipped with digital.jpg)

tonnage monitor in which the force exerted in forming process is measured and recorded by strain gauges. When the maximum permissible force is exceeded, the

system displays a warning message and cycle stops, to prevent possible damage to the press. Photoelectric sensors mounted on both columns front and back.

Ram and Guiding System

Ram is of high-quality cast steel and is guided in four guides at.jpg)

45 degree with continuous lubrication, so that it is able to

maintain constant clearance in spite of heat expansion. Bronze

and steel are used as guide pairs.

Advantages over hydraulic double actions:

- Increased production capacity due to superior reliability and improved performance.

- Large working capacity/safeguarding by means of overload protection.

- Exact adjustment and maximum repeat accuracy of the energy output.

- Wide range of stroke control options.

- Optimized, exact ram guidance.

- Optimum controllability of the forging process

- Reduced energy consumption and noise emission.

- Long lifetime and operational safety due to robust design.

- The spring stiffness of the frame is precisely adjusted by pre-tensioned tie rods.

- High press stroke rate even at low forming energies.

- Low maintenance and service costs

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automotive Press Machine Category

Servo Feeder Press Machine

Price 5000000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Automatic feeding of sheet metal to press machine

Material : Mild Steel

Dimension (L*W*H) : 1500 mm x 800 mm x 1600 mm Millimeter (mm)

Voltage : 220380 V Volt (v)

Ring Frame Double Action Press Machine

Price 5000000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Application : Compressing and pressing waste cotton/cotton rags in ring frame

Material : Mild Steel

Dimension (L*W*H) : 1600 mm x 1100 mm x 1800 mm

Voltage : 415 V

Blank Draw Press Machine

Price 5000000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Blank Drawing and Forming

Material : Mild Steel

Dimension (L*W*H) : 3100 mm x 2100 mm x 2800 mm Millimeter (mm)

Voltage : 380415 V (Three Phase) Volt (v)

|

SHARMA PRESSES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry